Sandia National Laboratories has developed a spinning heat-sink that floats on a hydrodynamic air bearing, and is capable of removing 30 times more heat than conventional heat-sinks of the same surface area. Not 30% more, but about 3,000% more; and that is on the first version prototype which was "badly unoptimized". Sandia is now working with version 3. The implications for thousands of industrial and consumer hardware applications are, to say the least, profound.

The hugely increased performance would have manufacturers salivating world-wide, if that was all it offered, but it gets much better. This technology is so quiet as to be almost completely inaudible. It is physically robust, and can be used in any physical orientation. The Sandia Cooler is practically immune to dust fouling; and drum-roll please, very cost-efficient to manufacture and implement with common materials.

Already, two unspecified companies have licensed the technology: one has plans to use it for cooling computer CPUs, and the other will apply it to LED lighting to greatly increase the amount of light that LEDs can produce. In addition to removing far more heat with a much smaller heat-sink, the benefits of increased energy efficiency will make the Sandia Cooler attractive for applications in HVAC, automotive, appliances, computers of all kinds and sizes, and countless other industries and devices.

Let's Get Technical, But Not Too Much

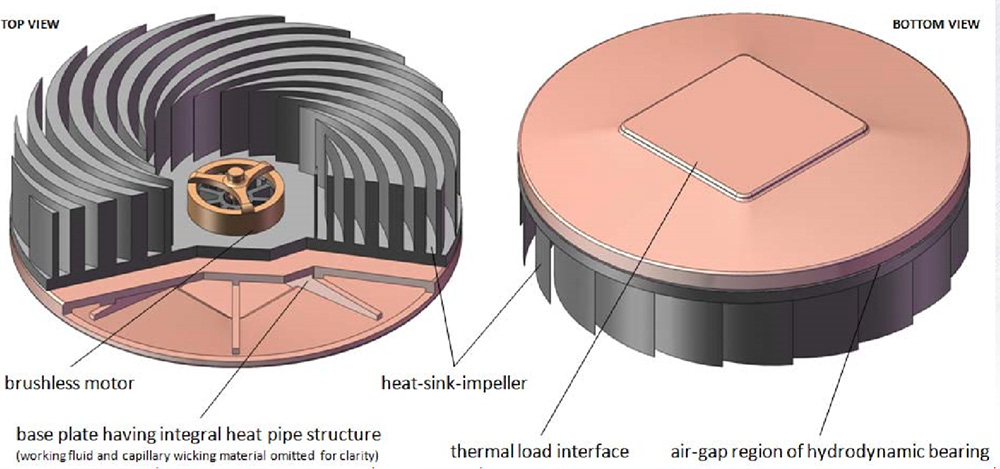

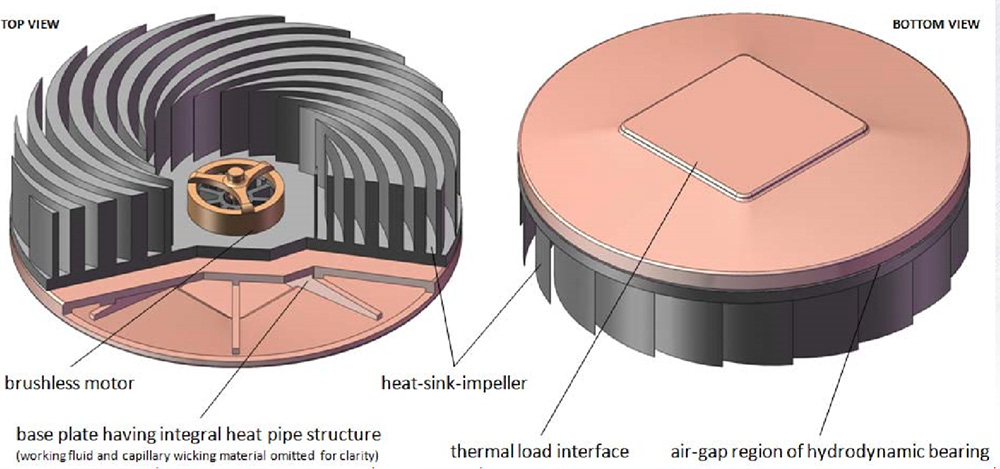

In order to grasp the way the Sandia Cooler does its work it really is necessary to first look at both top and bottom images of a prototype.

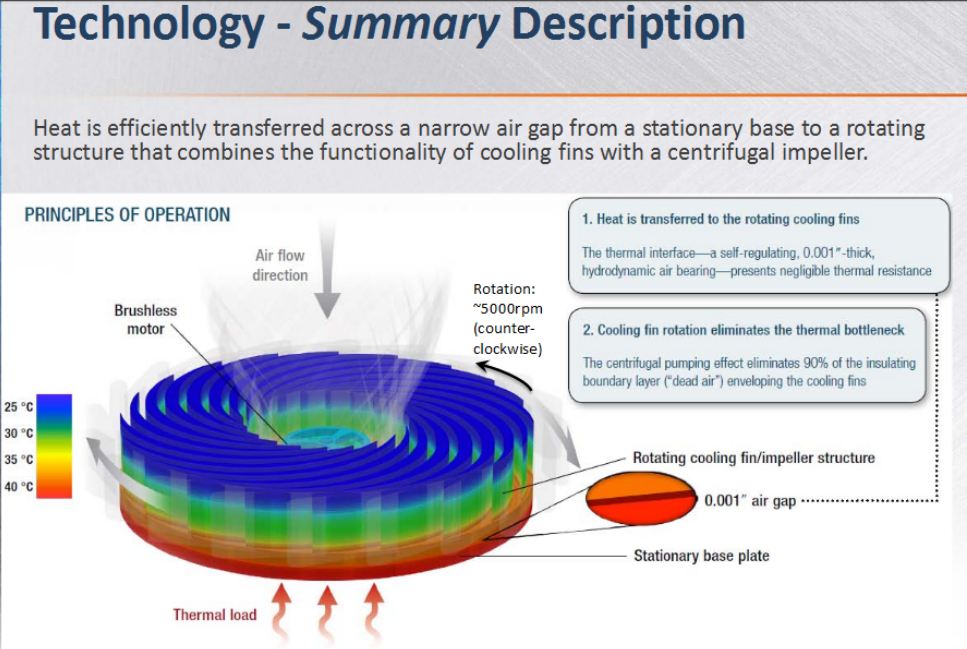

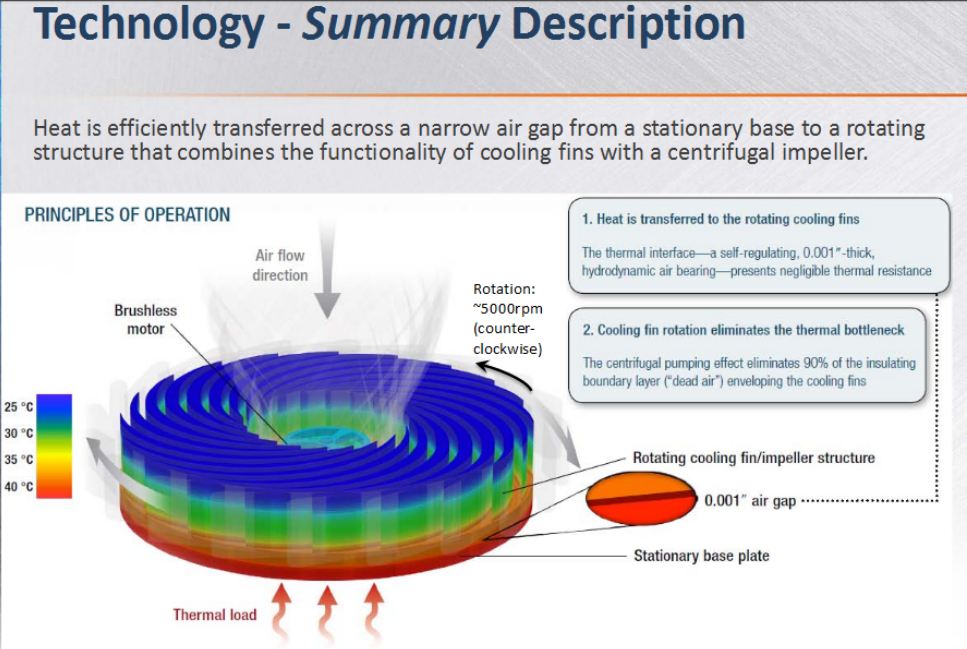

The first prototype spins at about 2,000 RPM and later models are planned at approximately 4,000 RPM, but will still be virtually silent. A base-plate, with built-in heat-pipes, can sit directly on a CPU, or other heat-source. Above that is a secondary base-plate which absorbs heat and forms a base for a brushless motor spindle, which keeps the heat-sink-impeller centered.

As the impeller spins up to speed, it draws in, and floats upon, a layer of air only one-thousandth of an inch thick, in much the same way that an air-hockey puck is supported by a process similar to hydroplaning. In an air bearing the gap distance is not caused or maintained by tight physical mechanical tolerances, and the air behaves like a very short and exceedingly stiff compression spring. Contrary to what might first be assumed, the behavior of a cushion of air only one-thousandth of an inch thick makes air bearings rugged, reliable, and extremely mechanically stiff.

Even though air is usually an insulator, the minimal thickness of the hydrodynamic (self pressurizing) air bearing layer underneath the impeller's base actually causes the small remaining amount of air to become a heat conductor, thereby transferring heat from the secondary base-plate into the impeller blades. An added advantage is that shearing forces in the air between the secondary base-plate and impeller, act to force dust particles tangentially out of the unit.

Aircraft flight surfaces, as an example, are aerodynamically designed to first split the air-flow, and then rejoin it as it departs the aircraft to reduce drag, and decrease the amount of energy needed to move an aircraft forward. The same design principles have been employed on the Sandia Cooler heat-sink-impeller blades. As a result, the amount of energy needed to spin the impeller is reduced by contrast to a conventional fan. Another outcome is greatly reduced noise output, making this technology virtually silent when enclosed in a computer or other device.

The Sandia Cooler air bearing heat-sink-impeller technology has been validated by independent analysis carried out by a third-party private company with extensive expertise in fluid dynamic modeling. They concluded that the Sandia Cooler stands out by comparison to conventional CPU coolers. Some estimates indicate that the United States could reduce energy consumption by 7% if Sandia Cooler technology is implemented in thousands of consumer and industrial applications.

Assessment

The primary barrier to faster computer CPUs has been thermal dissipation limits. When Sandia Cooler technology is implemented at the consumer level, as it certainly will be, get ready for much faster, quieter, and cooler computers and other devices.

When combined with other advances and laptop trends such as super lithium-ion batteries, high PPI count displays, tactile touchscreens, and advanced hybrid convertible form-factors, 2014 laptops will be an interesting breed indeed.

Laptop & Tablet Parts

Laptop & Tablet Parts

One Response to Sandia Cooler Air Bearing Heat-Sink-Impeller is Quiet & Dust-Immune – Expect Much Faster CPUs